Cet article a été traduit de l'anglais, contactez-nous si vous souhaitez améliorer cette traduction.

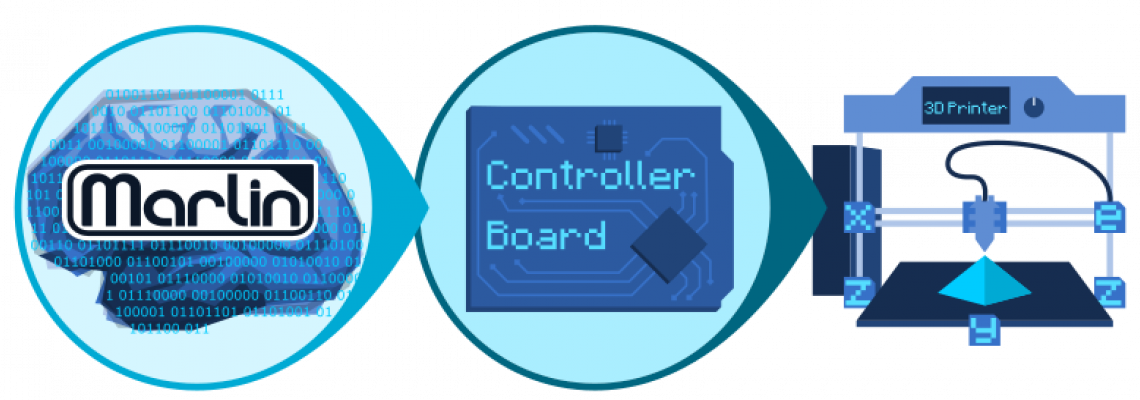

Qu'est-ce que Marlin?

Marlin est un micrologiciel open source pour la famille RepRap de prototypeurs à réplication rapide - communément appelé «imprimantes 3D». Il était dérivé de Sprinter et grbl, et est devenu un projet open source autonome le 12 août 2011 avec sa version Github. Marlin est sous licence GPLv3 et est gratuit pour toutes les applications.

Dès le départ, Marlin a été conçu par et pour les passionnés de RepRap pour être un pilote d'imprimante simple, fiable et adaptable qui «fonctionne tout simplement». En témoignage de sa qualité, Marlin est utilisé par plusieurs imprimantes 3D commerciales respectées. Ultimaker, Printrbot, AlephObjects (Lulzbot) et Prusa Research ne sont que quelques-uns des fournisseurs qui expédient une variante de Marlin. Marlin est également capable de piloter des graveurs CNC et laser.

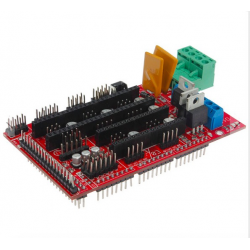

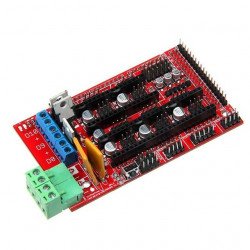

L'une des clés de la popularité de Marlin est qu'il fonctionne sur des microcontrôleurs Atmel AVR 8 bits peu coûteux - Marlin 2.x a ajouté la prise en charge des cartes 32 bits. Ces puces sont au centre de la populaire plate-forme Arduino / Genuino open source. La plate-forme de référence pour Marlin est un Arduino Mega2560 avec RAMPS 1.4 et Re-Arm with Ramps 1.4.

En tant que produit communautaire, Marlin vise à être adaptable à autant de cartes et de configurations que possible. Nous voulons qu'il soit configurable, personnalisable, extensible et économique pour les amateurs et les vendeurs. Une construction Marlin peut être très petite, pour une utilisation sur une imprimante sans tête avec seulement du matériel modeste. Les fonctionnalités sont activées au besoin pour adapter Marlin aux composants ajoutés.

Caractéristiques principales

- Code G complet avec plus de 150 commandes

- Suite complète de mouvements de code G, y compris les lignes, les arcs et les courbes de Bézier

- Système de mouvement intelligent avec anticipation, mouvement basé sur les interruptions, accélération linéaire

- Prise en charge de la cinématique cartésienne, Delta, SCARA et Core / H-Bot

- Commande de chauffage PID en boucle fermée avec auto-réglage, protection thermique, coupure de sécurité

- Prise en charge de jusqu'à 5 extrudeuses plus un lit d'impression chauffé

- Interface utilisateur du contrôleur LCD avec plus de 30 traductions linguistiques

- Impression sur carte hôte et sur carte SD avec démarrage automatique

- Compensation de nivellement du lit - avec ou sans sonde de lit

- Avance linéaire pour l'extrusion basée sur la pression

- Prise en charge de l'extrusion volumétrique

- Prise en charge du mélange et des multi-extrudeuses (Cyclope, Chimère, Diamant)

- Prise en charge des capteurs de fin de course / largeur de filament

- Minuterie et compteur d'impression

Comment Marlin fonctionne:

Le micrologiciel Marlin s'exécute sur la carte principale de l'imprimante 3D, gérant toutes les activités en temps réel de la machine. Il coordonne les éléments chauffants, les moteurs pas à pas, les capteurs, les lumières, l'écran LCD, les boutons et tout le reste impliqué dans le processus d'impression 3D.

Marlin met en œuvre un processus de fabrication additive appelé Fused Deposition Modeling (FDM) - alias Fused Filament Fabrication (FFF). Dans ce processus, un moteur pousse le filament en plastique à travers une buse chaude qui fond et extrude le matériau tandis que la buse est déplacée sous le contrôle de l'ordinateur. Après plusieurs minutes (ou plusieurs heures) de pose de fines couches de plastique, le résultat est un objet physique.

Le langage de contrôle pour Marlin est un dérivé du code G. Les commandes de code G indiquent à une machine de faire des choses simples comme «régler le chauffage 1 à 180 °» ou «passer à XY à la vitesse F.» Pour imprimer un modèle avec Marlin, il doit être converti en G-code à l'aide d'un programme appelé «slicer». Étant donné que chaque imprimante est différente, vous ne trouverez pas de fichiers G-code à télécharger; vous devrez les découper vous-même.

Lorsque Marlin reçoit des commandes de mouvement, il les ajoute à une file d'attente de mouvements à exécuter dans l'ordre reçu. L '«interruption pas à pas» traite la file d'attente, convertissant les mouvements linéaires en impulsions électroniques synchronisées avec précision vers les moteurs pas à pas. Même à des vitesses modestes, Marlin doit générer des milliers d'impulsions pas à pas chaque seconde. (par exemple, 80 pas par mm * 50 mm / s = 4000 pas par seconde!) Étant donné que la vitesse du processeur limite la vitesse à laquelle la machine peut se déplacer, nous recherchons toujours de nouvelles façons d'optimiser l'interruption pas à pas!

Les éléments chauffants et les capteurs sont gérés dans une seconde interruption qui s'exécute à une vitesse beaucoup plus lente, tandis que la boucle principale gère le traitement des commandes, la mise à jour de l'affichage et les événements du contrôleur. Pour des raisons de sécurité, Marlin redémarrera réellement si le CPU est trop surchargé pour lire les capteurs.

Impression de choses

La modélisation

Alors que Marlin n'imprime que du code G, la plupart des trancheurs ne découpent que des fichiers STL.

Quoi que vous utilisiez pour votre chaîne d'outils de CAO, tant que vous pouvez exporter un modèle solide, une trancheuse peut le «découper» en code G et le micrologiciel Marlin fera de son mieux pour imprimer le résultat final.

Avant que Marlin puisse rêver d'imprimer, vous aurez d'abord besoin d'un modèle 3D. Vous pouvez télécharger des modèles ou créer les vôtres avec l'un des nombreux programmes de CAO gratuits, tels que FreeCAD, OpenSCAD, Tinkercad, Autodesk Fusion 360, SketchUp, etc.

Un niveau élevé de connaissances est nécessaire pour modéliser des objets complexes comme un crâne T-Rex, mais d'autres objets peuvent être assez simples à modéliser. Pour obtenir des idées et tester des choses, explorez des sites comme Thingiverse et YouMagine et imprimez des choses pour le plaisir.

Tranchage

Les tranches préparent un modèle 3D solide en le divisant en fines tranches (couches). Dans le processus, il génère le code G qui indique à l'imprimante dans les moindres détails comment reproduire le modèle. Il existe de nombreuses trancheuses parmi lesquelles choisir:

- Cura.

- Slic3r.

- PrusaSlicer (anciennement Slic3r Prusa Edition) Le nouveau Kid sur le bloc basé sur Slic3r.

- Simplify3D est une offre commerciale.

Impression

Marlin peut être contrôlé entièrement à partir d'un hôte ou en mode autonome à partir d'une carte SD. Même sans contrôleur LCD, une impression SD autonome peut toujours être lancée à partir d'un hôte, de sorte que votre ordinateur peut être détaché de l'imprimante.

Le logiciel hôte est disponible pour plusieurs plates-formes, y compris les systèmes de bureau, Raspberry Pi et les tablettes Android. Tout appareil doté d'un port USB et d'un terminal série peut techniquement agir en tant qu'hôte, mais vous bénéficierez d'une meilleure expérience d'impression en utilisant un logiciel hôte spécialement conçu pour les imprimantes 3D. Les sélections actuelles incluent:

Pronterface est un hôte open source de Kliment.

Repetier Hostest un hôte de source fermée par Repetier Software.

OctoPrint est un hôte open source pour Raspberry Pi de Gina Häußge.

Cura est un hôte open source par Ultimaker. (AVERTISSEMENT: vous ne pouvez plus sélectionner manuellement le port et la vitesse de communication, votre imprimante doit être détectée automatiquement par Cura)

Simplify3D comprend à la fois un hôte et une tranche.

De nombreuses imprimantes 3D sont livrées avec une version personnalisée de Repetier ou Cura. Bien que cela aide à associer la marque de l'imprimante à un logiciel complémentaire, ces versions sont généralement obsolètes et reçoivent peu de mises à niveau. Nous vous recommandons plutôt de télécharger la dernière version générique de votre logiciel hôte préféré.

Installation de Marlin

Pour installer Marlin sur votre imprimante, vous devez d’abord télécharger Marlin, puis modifier vos fichiers de configuration, et enfin utiliser un IDE pour Compiler le projet Marlin sous forme binaire et le télécharger sur votre carte. Le processus de construction peut sembler intimidant au début, mais après l'avoir fait plusieurs fois, vous serez un pro.

Marlin n'a besoin d'être re-flashé que lorsque les paramètres fixes sont modifiés dans les fichiers de configuration. De nombreux paramètres ne sont que des paramètres par défaut et peuvent être modifiés (et enregistrés dans l'EEPROM) avec des codes G. Consultez la description de chaque option dans les fichiers de configuration pour savoir quels codes G s'appliquent.

Télécharger

Commencez par télécharger le code source de Marlin. Il y a quelques bases de code parmi lesquelles choisir.

| Download 2.0.x | Télécharger 2.0.x Version actuelle |

| Download 1.1.x | Télécharger 1.1.x Version précédente |

| Download 1.0.x | Télécharger la version 1.0.x plus ancienne |

| Download bugfix-1.1.x | Téléchargez la version «Nightly» de bugfix-1.1.x. Procéder avec prudence! |

| Download bugfix-2.0.x | Téléchargez la version «Nightly» de bugfix-2.0.x. Procéder avec prudence! |

| Download dev-2.1.x | Téléchargez la version «Nightly» de dev-2.1.x. Procéder avec prudence! |

Marlin 2.0 et versions ultérieures prennent en charge ARM 32 bits. PlatformIO n'est pas requis pour les cartes AVR.

Configurer:

Pour configurer Marlin, vous pouvez utiliser l'IDE Arduino ou votre éditeur de texte préféré pour modifier les fichiers Configuration.h et Configuration_adv.h. Voir Configuring Marlin for plus de details.

Construire et installer:

La procédure d'installation de Marlin peut varier selon la version de Marlin que vous souhaitez installer et la carte sur laquelle vous installez. Une fois que votre environnement de build Marlin est configuré, l'installation des mises à jour peut se faire en un clic.

| Marlin Version | Platform(s) | Instructions |

|---|---|---|

| 1.1.x or 2.x | 8-bit AVR | Install Marlin with Arduino IDE |

| 1.1.9 or 2.x | 8-bit AVR, 32-bit ARM | Install Marlin with PlatformIO |

| 2.0 | LPC1768 (Re-Arm) | Install Marlin on Re-ARM |

Vous recherchez des exemples de configurations pour votre machine?

- Marlin 1.1.x: inclus dans le dossier ‘example_configurations’.

- Marlin 2.0.x : Hosted separately. Links sur la page mrlin Downloads.

Sources;

- https://marlinfw.org/docs/basics/install.html

- http://www.tobiasschuerg.de/3d%20printing/2019/12/08/geeetech-a10-marlin-v2.html

7 Commentaire (s)

Très intéressant

très bonne initiative ,on aimerai bien avoir plus de détailles sur l\'impression 3d et surtout les défauts d\'impression et comment on remédie a ça.\r\nbonne chance bonne continuation #.

If you enjoy a mix of traditional and modern games, the goa game apk is perfect for you. It offers a diverse catalog that keeps every gaming session fresh and engaging. The installation process is straightforward, ensuring you spend more time playing and less time waiting. Join the growing community and start winning rewards.

Lottery7 Game works well on mobile phones without any performance issues.

Tiranga Game performs well on mobile devices with stable gameplay.

Big Mumbai Game works smoothly on mobile devices and loads quickly.

I never face issues with Big Mumbai login, which makes accessing my account stress-free. The process is fast, secure, and straightforward, ensuring I can start playing immediately. I also like that the system has extra layers of protection for user safety. Big Mumbai login is very user-friendly, allowing players of all ages to enjoy the platform without complications. It’s a great feature that enhances the overall experience.

Laissez un commentaire